Depends on who you have I guess. I worked for ExxonMobil 33 years, have designed and executed about 10 projects, some of which half a billion dollar projects, I was global process control #1 (Lead Specialist) for High Pressure PolyEthylene and Aromatics, headquarterd in Houston and working out of Antwerp: global support works better if you are on UTC. Supported US, Europe, Saudi Arabia, Singapore and Thailand. Was #1 process control in HPPE Licensing, made the design packages for process control for over 10 Licensees, gave them training, helped with start-up issues, provided counseling once they were running… helped write the ExxonMobil Process Control Practices, our rulebook for design… you get the picture, I guess. My expertise goes from field wiring all the way up to safety systems, process control and also advanced process control: last 10 years of my career I roamed the world with our #1 DMC specialist building multivariable model based control, some of which were 40 manipulated variables and 80 controlled variables large… to make these work you need to understand everything, from the process to the equipment, the wiring, the instrumentation, the control systems and (sufficiently) advanced math. I’ve been around a bit. I’ve done more than that, also did fault insertion testing on digital equipment for process control, examining the failure modes of instrument transmitters, control and safety systems… certifying for use in our company and when not good enough, advising the manufacturers how to improve their stuff to improve reliability and safety of their digital systems…I’m electronics by background.

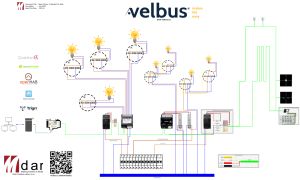

That is why I chose Velbus. It uses CANbus, probably the most used protocol in the world or certainly up there with TCP/IP. It is a real distributed control system for the home and therefore superior to any competing home automation in the world in terms of reliability and compatibility over the years. The native application features are somewhat limited, but that is what you get with the choice and that is fine. The only thing it lacks is a VARPR, a VARiable PRocessor or Applications Module to make the more complex stuff. But that may not be a thing that would have massive commercial success. The Signum falls terribly short, it is merely a gateway to the hackers and I don´t like that. I wish for a native VARPR. No connection to the hackers.

There is not going to be an issue with producing the VELBUS chips, the world is invested heavily in these. It is “open” in terms of hardware, very rare. But … programing native VELBUS and getting it to do what I want still proved to be a challenge sometimes, even for me :-). I’ve forgotten a lot of the intricate stuff by now, everything runs fine since 2016 and I’m rarely touching it these days. I should write documentation for my system, I fear with my passing people might find it a challenge to maintain…

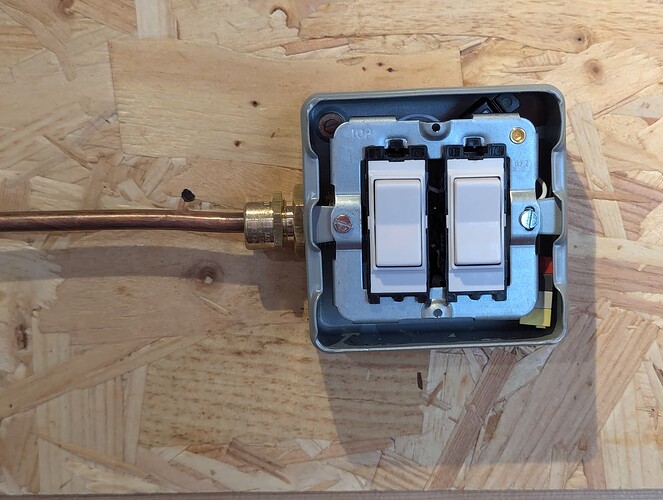

Anyway, you decide what to do with fire proofed installation of Velbus. I wouldn´t bother. Digital Emergency back-up systems located in a fire don´t make any sense to me. If having light is the issue, even LEDs will prove to be inferior to incandescent bulbs. LEDs are silicon based semiconductors or similar, they cannot stand the heat of a fire. The wiring to the fixtures should be fire proofed for the run in fire hazardous area, then cabling should be run to a safe location where a mechanical switch can be used to turn it on or off. Then test the system every quarter.